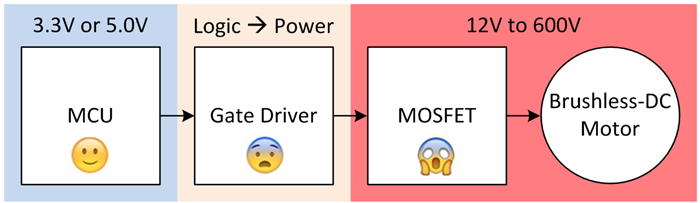

Most three-phase inverters use insulated gate bipolar transistors (IGBTs) in applications like variable-frequency drives, uninterruptible power supplies, solar inverters and other similar inverter applications. Each phase of a three-phase inverter uses a high- and low-side IGBT to apply an alternating positive and negative voltage to the motor coils. Pulse-width modulation (PWM) to the motor controls the output voltage.

The three-phase inverter also uses six isolated gate drivers to drive the IGBTs. Apart from the IGBTs and isolated gate drivers, three-phase inverters include DC bus voltage sensing, inverter current sensing and IGBT protection like over temperature, overload and ground fault.

Cost and performance are challenging trade-offs in many end applications like heating, ventilation and air conditioning (HVAC), solar pumps and appliances.

So what are the best ways to save bill of materials (BOM) cost without compromising system performance? Here are some tactics:

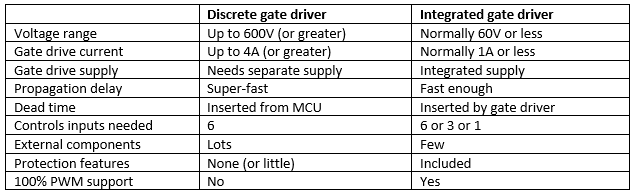

- Combine the high- and low-side drivers into a single package. A three-phase inverter requires six IGBT gate drivers. You can use individual gate drivers for each IGBT, but a dual-channel gate driver helps with design flexibility and reduces BOM cost.

- Power the gate drivers with a bootstrap. Needless to say, any high-voltage inverter application will need isolation between the primary and secondary side of the gate driver for reliable operation. The isolated gate drivers may need different supplies for the high and low sides. Instead of using six different isolated supplies for a three-phase inverter, a bootstrap power supply reduces the power-supply requirements to only one, thus reducing total BOM cost and board space.

- Protect the IGBTs using simple comparators. You can achieve simple overload and short-circuit detection by sensing the current and using window comparators. The comparator output can disable the IGBT gate drivers with the DISABLE function.

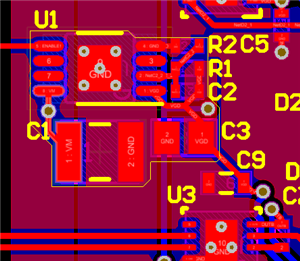

TI’s newly released UCC21520 is a reinforced isolated dual channel gate driver. With best in class propagation delay of 19ns (typical), programmable dead time and wide voltage ranges make it really suitable for such inverter applications.

Apart from the IGBTs, the IGBT gate drivers and current sensing play a major role in determining the cost and performance of the three-phase inverter stage. Consider the following tactics save BOM in current sensing circuit:

- Shunts. Instead of bulky and costly hall and fluxgate current-sensor modules, shunts optimize the cost and space of sensing circuits. Current transformers are also considered but have issues with linearity and performance compared to shunt.

- In-phase current sensing for better sensing performance (compared to leg current sensing). In-phase current sensing means that there is a constant motor current flowing through the shunt (compared to a noisy switching current in leg current sensing), regardless of which IGBT is switching. Also, it is easy to detect terminal-to-terminal shorts and terminal-to-GND shorts. You can also use two shunts for cost optimization and calculate the current of the third phase in software by using data from the other two sensing circuits.

- Consider using isolated amplifiers along with a shunt instead of a hall current sensor. Using isolated sigma-delta modulators for current sensing requires digital filters implemented in software or hardware. An isolated amplifier enables interfacing with low-cost microcontrollers with a built-in SAR ADC.

- Simple overcurrent protection. High-bandwidth isolated amplifiers and comparators with fast response times (<5 to 6µs) enable fast overcurrent protection for inverters, thus allowing you to use cost-effective gate drivers in your system.

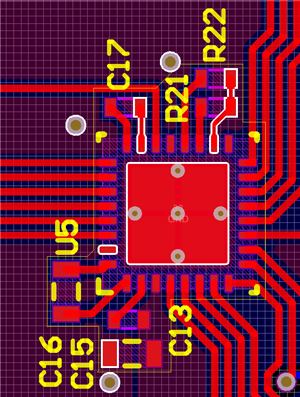

AMC1301 is TI’s newly released precision reinforced isolated amplifier. It is optimized for direct connection to shunt resistors and supports accurate current control. The high linearity and low temperature drift of offset and gain errors of the AMC1301 results in system-level power savings and lower torque ripple. With 3µs delay and detection feature of missing high-side supply makes is suitable for motor drives applications.

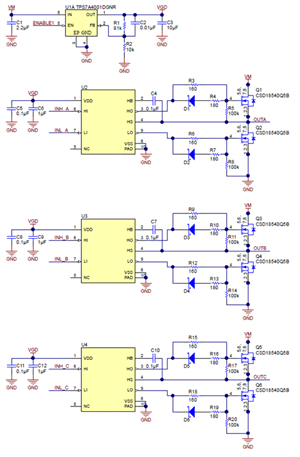

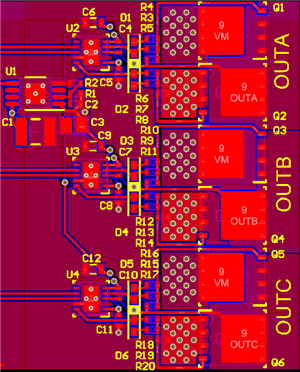

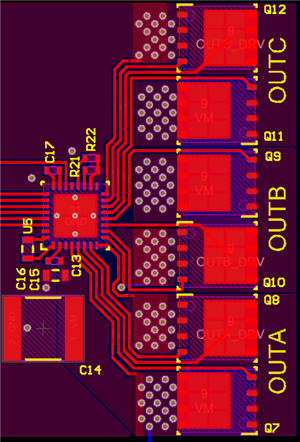

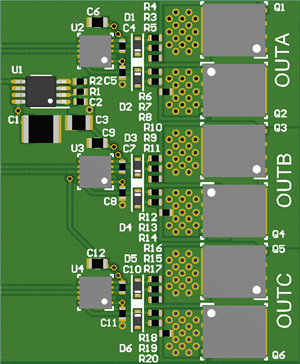

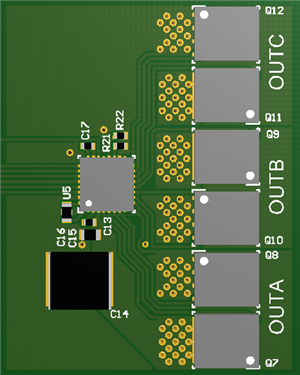

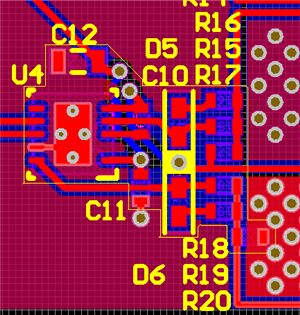

The new TI Designs Reference Design for Reinforced Isolation 3-Phase Inverter with Current, Voltage and Temp Protection (TIDA-00366) provides a reference solution for a three-phase inverter rated up to 10kW. Figure 1 is a high-level block diagram.

Figure 1: High-level block diagram of TIDA-00366

The design includes the UCC21520 reinforced isolated dual-IGBT gate driver, AMC1301 reinforced isolated amplifier and TMS320F28027 MCU. A lower system cost is possible by using the AMC1301 to measure motor current (interfaced with the MCU’s internal ADC), with a bootstrap power supply for the IGBT gate drivers. The inverter is designed to have protection against overload, short circuit, ground fault, DC bus undervoltage and overvoltage, and IGBT module over temperature.

What techniques do you use for saving the BOM? Tell us.

Additional Resources:

- View the video The power of isolated gate drivers

- Blog posts:

- White papers:

- UCC21250 application note: A Universal Isolated Gate Driver with Fast Dynamic Response

- AMC1301 application note: How to Optimize AMC1301 in Voltage Sensing